Higher Dry Content, Lower Energy Use with Customised QualiFlex Press Sleeves

How does the fully customisable QualiFlex press sleeve portfolio achieve higher dewatering performance and dry content after press? At the Voith Paper Technology Centre, a team of multidisciplinary experts are hard at work identifying innovative opportunities for continuous improvement. Discover how cutting-edge MicroCT analysis, lab tests and test rigs, as well as real-world field trials, secure the best results for every type of paper mill – even under the most challenging of conditions.

Slice by slice, the remarkable benefits of the QualiFlex press sleeve portfolio are revealed for all to see.

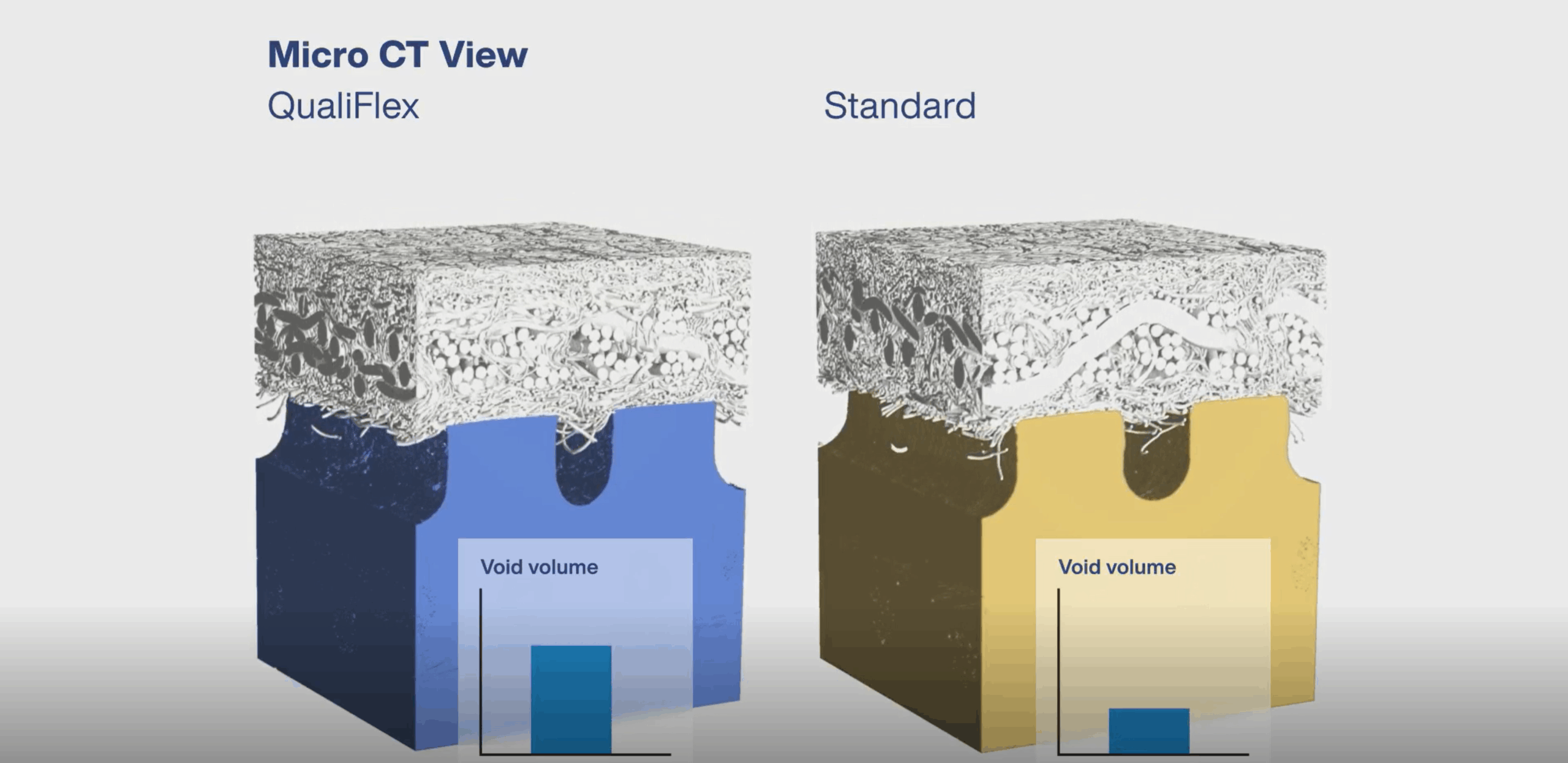

What we are doing is unique in the industry. With our cutting-edge MicroCT analysis tool, we can see inside new and used press sleeves. This gives us a better understanding of the groove design, void volume and material properties that maximise dewatering performance and ensure a long, stable and reliable lifetime of our QualiFlex family.

Dr. Christina Bauer, Global Product Manager Press Roll Covers at Voith Paper

Long-term studies using the MicroCT tool confirm that the QualiFlex reputation for reliable and superior dewatering properties is rightfully earned, noted Bauer. “Time and time again, the MicroCT analysis confirms that the combination of our patented material and customised designs ensures that the void volume of our grooves remains consistent over a longer service life. Such superior and stable void volume is key to efficient water flow, which leads to effective and efficient dewatering in the press section.”

R&D for a longer service life with superior dewatering properties

This assessment is echoed by Peter Weichenberger, Business Unit Manager QualiFlex at Voith Paper. “Our MicroCT technology allows us to scientifically investigate the performance of press sleeves in real-world conditions. Our customers increasingly value our science-backed R&D methodology, which clearly visualise the benefits of our press sleeves for their production lines.”

What’s more, such in-depth analysis means that Voith can accurately and individually customise the design of each QualiFlex press sleeve to achieve a higher dry content after the press for every type of paper grade and paper mill.

A higher dry content is the goal of any papermaker, as it ultimately leads to reduced steam and energy consumption and/or higher production capacity. The MicroCT analysis helps us secure excellent dewatering properties over a longer, stable service life for every kind of paper mill.

Peter Weichenberger, Business Unit Manager QualiFlex at Voith Paper

Unique MicroCT analysis on dewatering performance

One recent field study in particularly demanding conditions compared the performance of a customised QualiFlex press sleeve to an alternative from another manufacturer. Both were used in the one and only shoe press on a paper machine to produce the same quality of paper. While the QualiFlex showed excellent dewatering performance for 145 days, the alternative had to be replaced after only 64 days due to poor dewatering results.

Back in the lab at the Voith Paper Technology Centre, the R&D innovation hub in Heidenheim, Germany, the QualiFlex specialists got to work to identify the root causes for the marked differences in performance. The MicroCT analysis looked at the void volume of the grooves on the press sleeves before and after hydrolysis treatment under various pressures up to 7MPa.

Essentially, Voith’s MicroCT analysis uses advanced X-ray technology and computer algorithms to see inside the press sleeves slice by slice and create high-resolution, three-dimensional images of the small grooves in the sleeves. This allows for detailed structural analysis and precise measurement of material properties.

The QualiFlex press sleeve stands out for stability and resilience

Among the key findings of the MicroCT analysis, two are especially interesting for papermakers. First, it showed that the initial void volume of the grooves in the new QualiFlex press sleeve was much higher that the grooves in the unused alternative. Second, at the end of the service life of 145 days, the QualiFlex press sleeve still had a remaining void volume of 348cm3/m2.

Most notably, the MicroCT analysis showed that this end capacity for the QualiFlex press sleeve was close to the initial void volume of the alternative, which was 358cm3/m2 at the outset. At the end of its service life of only 64 days, the alternative ended with a far lower capacity of only 288cm3/m2. This explains the poorer dewatering effect. An overview of several MicroCT studies is available upon request from Christina Bauer (christina.bauer@voith.com).

“These types of comprehensive comparative studies confirm not only that QualiFlex has better initial pressure resistance, but that our patented material and groove designs are significantly superior when it comes to withstanding the harsh conditions and pressure of the paper machine over time,” noted Bauer. “This is essential to ensure stable and consistent, high dewatering performance over a longer period, whatever the conditions at the mill.”

For one European paper mill with an annual production capacity of around 200,000 tons of fluting and testliner between 110g/m2 and 215g/m2, the higher dewatering performance of QualiFlex press sleeves was evident after a temporary switch to a press sleeve from another manufacturer. The QualiFlex press sleeve had recorded a stable and efficient dewatering performance over 451 days. In contrast, within 140 days with a third-party alternative, the press section already showed increased misting around the press sleeve. Initial investigation of the issue suggested that the misting was likely caused by the heavy wear and swelling of the surface of the third-party press sleeve, which was unable to withstand the harsh conditions of this particular paper mill.

A focus on continuous improvements in R&D for press sleeves

The MicroCT analysis tool is not just about measurement. It is also a powerful R&D tool for customer-centric innovation. Crucially, this one-of-a-kind research in the industry ensures that the Voith QualiFlex specialists can identify key opportunities for continuous improvement.

Continuous improvement is a key topic of interest at the Voith Paper Technology Centre, the R&D innovation hub in Heidenheim, Germany, where the in-depth MicroCT analysis takes place. It is also where the custom-made QualiFlex press sleeves are designed and manufactured using innovative, patented materials.

This clear focus on continuous improvement at the production site has led to further developments in the design, material use and manufacturing methods for the portfolio of QualiFlex press sleeves. Each improvement is aimed at ensuring a higher dry content after press with stable and reliable production.

Improving performance, reducing risk for customers

“We invest considerable sums in R&D and quality control for our press sleeves, which sets us apart from other suppliers,” explained Bauer. “It’s a luxury that gives us time to focus on continuous improvement and customer-centric innovations at our state-of-the-art research hub. We can then try our ideas out on test rigs that replicate conditions on paper mills before moving to real-world trials in close collaboration with our customers.”

This approach takes time, but there is a good reason for this. “Our way is specifically aimed at protecting our customers and giving them a competitive edge,” explained Bauer. “We never increase the risk for our customers.”

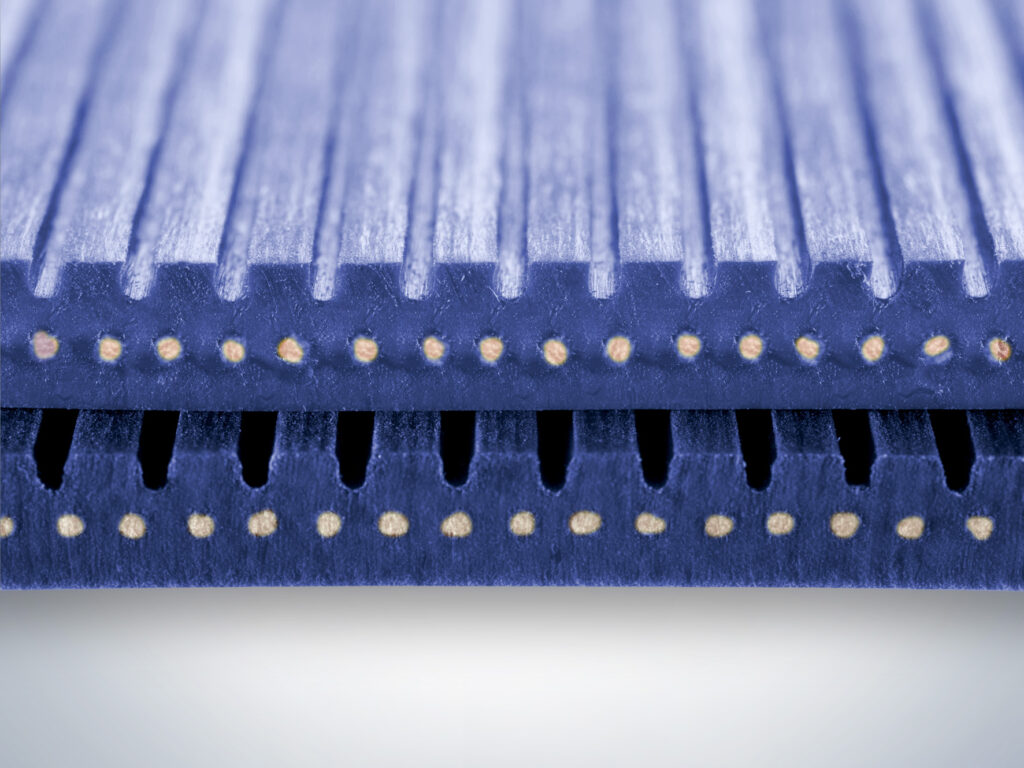

This tried-and-tested process has led to proven popular innovations with patented materials on the QualiFLex portfolio. These include the unique blind-drilled surface in the QualiFlex press sleeves that optimise the dewatering process. It is also why QualiFlex press sleeves are breaking world records in service life, measured both in terms of nip cycles and operating days.

In addition, the QualiFlex specialists have another key advantage on top of the cutting-edge research facilities, highlights Weichenberger. “We are members of a multidisciplinary team at a full-line supplier, which means we have access to every kind of insight, expertise and knowledge of process engineering that is necessary to ensure our innovations have a positive impact on the paper production process.

Greater impact resistance and mechanical strength

Another type of impact can be a considerable cause of concern for papermakers who produce board and packaging with higher grammage. When a paper wad of testliner makes its way through to the press nip in such production lines, for instance, it can suddenly increase the pressure on the press sleeve. The impact of such a paper wad can lead to damage on a press sleeve if it is not tough enough to withstand the shock.

Such wad impacts are relatively rare even in the harshest conditions at coard and packaging production lines. However, when they occur, they can lead to costly unscheduled maintenance shutdowns. This is why the QualiFlex team has been making use of the high-tech R&D facilities to research ways to ensure superior impact resistance of the press sleeves.

At the research hub, the QualiFlex specialists have replicated testliner wad impacts on a NipcoFlex test rig running at 800m/min with a line load of 1,100kN/m. Lab tests followed using various weights to simulate impacts under mill conditions. One key finding of the series of tests was that impact failure always starts with damage to the yarn structure.

“Our research shows that when the reinforced structure has higher impact resistance, the press sleeve itself is more durable in the long run,” explained Bauer. “This insight subsequently led to the development of a new type of reinforced structure with higher mechanical strength and flexibility in direction of the cross section for the QualiFlex portfolio.”

Tougher reinforced structure for increased flexibility and service life

Following the initial results of the research into the impact failures, the Voith specialists identified a way to improve the reinforced structure of the QualiFlex press sleeves to secure higher impact strength.

The first QualiFlex press sleeves with the new reinforced structure underwent extensive lab testing. Once the team was satisfied with the results, numerous field trials followed in close collaboration with customers around the world.

Currently, hundreds of QualiFlex press sleeves with the new reinforced structure are running successfully. The switch to the new reinforced structure has been smooth and viewed positively by customers involved in the trials.

The improved toughness and impact resistance of the new reinforced structure ensures that the QualiFlex press sleeves retain mechanical strength throughout the service life and have high wad and shoe crack resistance.

Solving the shoe edge cracking challenge

Increased shoe crack resistance is not a benefit that many papermakers will immediately notice, simply because shoe edge cracking of the QualiFlex press sleeve is not an issue for most papermakers. It generally occurs only under the most challenging conditions, and even then, only in the most demanding applications.

Nevertheless, shoe edge cracking was an occurrence that caught the attention of the QualiFlex specialists who saw it as another opportunity for continuous improvement.

Long-term rigorous trials and analysis at the research hub in HeidenHeim led to an innovative optimisation of the production process to further reduce the rare occurrences of shoe edge cracking. Repeated trials on test rigs confirmed that the press sleeves produced using the new process showed no signs of cracking.

“Although this particular improvement is not something that every papermaker will notice, it is something that benefits everyone,” highlighted Weichenberger. “Our manufacturing process ensures that our QualiFlex portfolio is designed to withstand the most challenging conditions – which leads to a longer stable service life for all applications.”

Superior performance through tailor service and support

As the QualiFlex press sleeves have such a long life, Voith ensures that customers are provided with long-term service over the entire life cycle. QualiFlex specialists and Voith engineers team up to offer a wide range of comprehensive support that is designed to improve not only the performance of the QualiFlex press sleeves but also the press section as a whole.

As a full-line supplier, Voith provides tailored service packages that include audits, maintenance and troubleshooting across the entire paper machine, not just the press section. Teams of experienced application engineers work closely with customers to optimise press sleeve designs for specific paper grades, machine layouts and production processes.

As an international organisation, the teams can leverage a global network of experts to solve issues. It is possible to draw on the collective knowledge of Voith engineers and resources across regions to quickly address any type of challenge that a customer might be experiencing in the press section – or elsewhere in the mill.

“By offering this level of comprehensive support and expertise, we are a true long-term partner to our customers,” explained Weichenberger. “ We help them maximise the efficiency and reliability of their paper production operations and make them fit for the future.”

Service portfolio improves planning of maintenance

One such innovative service is performed with the Voith Surface Scanner. “With this tool, Voith Service Engineers can perform essential inspections of the QualiFlex press sleeve during planned maintenance shutdown anywhere in the world,” explained Mario Neumann, Senior Global Application Manager at Voith Paper.

Unlike conventional inspections that generally use manual imprints and are known to overlook critical wear points, the self-driven Voith Surface Scanner automatically carries out a seamless full-width profile and delivers high-resolution images over the length of the press sleeve surface. Following detailed analysis of the void volume, the remaining lifetime of the press sleeve can be reliably calculated, and maintenance procedures can be efficiently planned.

Higher dry content leads to energy savings

All the research, innovative improvements and service options are geared to ensuring papermakers have fewer unplanned shutdowns and can better plan maintenance, which results in higher overall equipment efficiency (OEE) and lover operational costs.

In addition, as the superior dewatering performance of the QualiFlex press sleeve leads to a higher dry content, papermakers ultimately save steam and energy consumption in the dryer section. Generally, a 1 percent increase in dry content saves 4 percent in energy consumption. Papermakers can also choose to use that 1 percent increase in dry content to increase production by 4 percent.

One example of what a difference this all-round expertise and service can make is exemplified by another recent innovation: the HighPerformance Press solution. This consists of Voith’s NipcoPress Show Press technology, a new press concept, a tailored combination of press felts and QualiFlex press sleeves. Together, they contribute to an even higher dry content. Simulations show that, depending on the initial conditions, up to a 3 percent increase in dry content can be achieved, which reduces the steam consumption by up to 12 percent.

After installing HighPerformance Press, we have seen a higher dry content after the press section and lower steam consumption, which helps us reduce our carbon emissions.

Wouter Lap, Managing Director at Smurfit Kappa Roermond Papier

But the advantages don’t end there for the PM1, which has an operating speed of 1,250m/min, a sheet width of 5,000mm and an annual production capacity of 275,000 tons of high-performance lightweight packaging paper with basis weights between 80 and 135g/m2. “This solution also has a cost-price benefit,” Lap added. “And it has increased our machine capacity.”

Customised press sleeves and services for greater efficiency

The specific requirements and conditions differ greatly from one paper grade and mill to another. As a result, the ability to design, manufacture and service customised QualiFlex press sleeves is crucial for achieving the highest possible dry content after press on every type of machine and a higher runability.

Each QualiFlex press sleeve is therefore custom-made in the Coith Paper production site in Heidenheim, Germany. The portfolio covers all paper grades, and each press sleeve is tailored to the requirements of individual machines and mill conditions. During the production process, the surface of the QualiFlex press sleeves are treated to create the grooves, blind-drilled surface and distinct profiles that give the press sleeve some of its unique qualities.

Finding the perfect QualiFlex press sleeve for every type of paper machine is a fascinating process. Figuring out the best possible solution and seeing how our innovations maximise the optimisation potential of a paper mill is incredibly rewarding.

Dr. Christina Bauer, Global Product Manager Press Roll Covers at Voith Paper