Henkel and VTT Develop New Bio-based Foam E-commerce Packaging Material

Henkel teamed up with VTT to pilot a recyclable alternative to petroleum-based foam materials for e-commerce packaging. By building a dedicated pilot line, VTT helped Henkel take the next step and ultimately deliver a market-ready solution for its brand-owner customers.

Key facts

Challenge:Henkel sought to replace fossil-based foams used in packaging with a recyclable, renewable alternative made from cellulose foam.

Solution: VTT managed the construction of a dedicated pilot line to scale up Henkel’s material recipe from lab to industrial level – demonstrating technical feasibility and business value.

Benefits: As the end result, Henkel has a viable product, new intellectual property and a technology that can be transferred to customers’ production lines.

From plastic waste to fibre-based innovation

Plastics remain a dominant material in packaging, yet their environmental impact is clear. Around 8–10% of global fossil fuel production goes into manufacturing plastics and less than 12% of plastics are recycled. Every minute, a truckload of plastics ends up in our seas. As consumer expectations, regulation, and brand-owner commitments push industries toward circularity, the demand for renewable and recyclable packaging materials is growing rapidly.

VTT has been at the forefront of developing sustainable alternatives through foam forming technology, which allows wood-based fibres to be formed into lightweight, versatile materials. This innovation opens up possibilities to replace conventional plastics with renewable solutions in packaging and beyond.

Tailored pilot line helps cross “valley of death”

According to Bradley McLeod, Business Development Director at Henkel, sustainability has always driven innovation at the company, and one of the sustainability challenges they identified was the need to replace fossil-based foams in packaging.

“We had an idea of using cellulose foam as an alternative material and needed a research partner to bring our vision to reality. VTT had previously worked on creating lightweight papers and molded packaging from cellulose foam. They had the right equipment, the right people, and a strong focus on research, which made them a great fit for what we were trying to achieve,” said McLeod.

What began as a research-focused effort on lab scale quickly grew into something bigger. Elina Pääkkönen, Senior Scientist at VTT explained that Henkel already had a functioning recipe for their product, but needed help in upscaling – crossing the critical “valley of death” between lab-scale development and commercial viability – first to semi-pilot scale and then to a full-scale pilot.

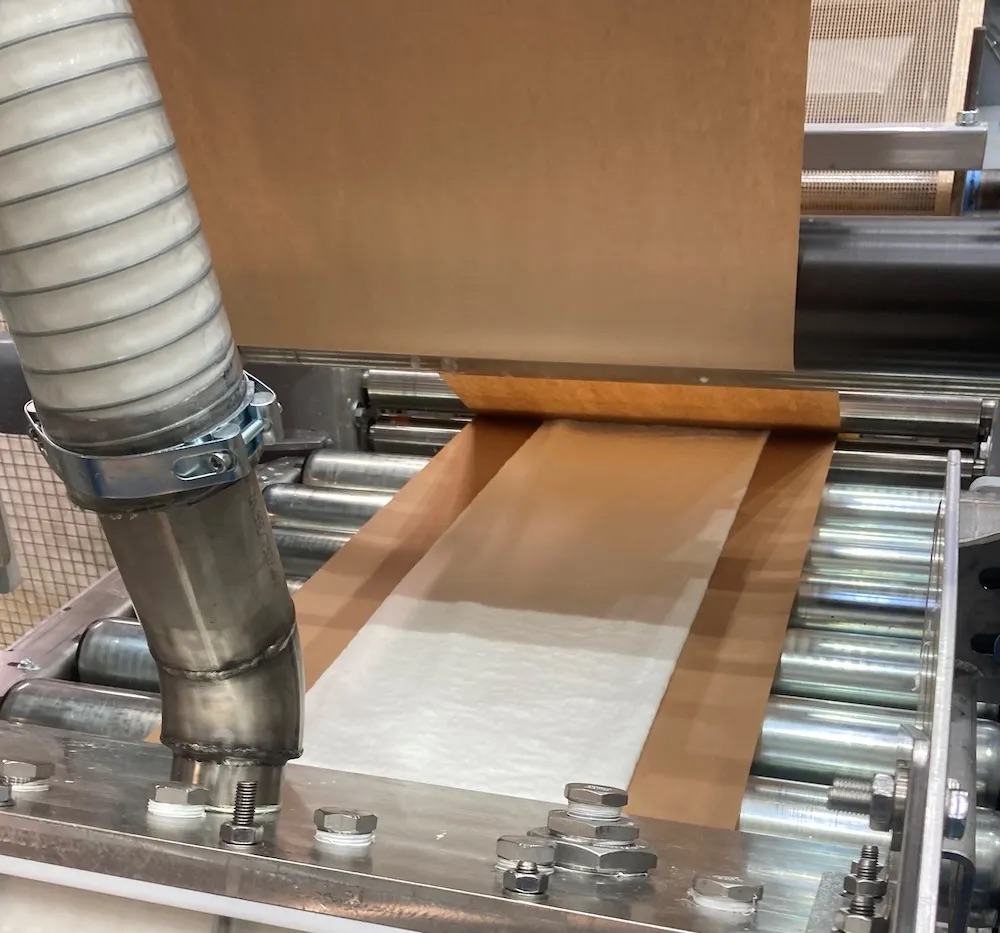

“What makes this project unique is that we built a completely new full-speed pilot line specifically for Henkel at our facility in Jyväskylä, clearing an entire hall for this purpose – something we had never done before,” said Pääkkönen.

Over a lengthy period of test runs, Henkel even invited their own brand-owner customers to witness the process. This resulted in convincing one of the customers to transfer the line to their own premises in the US.

Research expertise powers industrial scale-up

As part of the collaboration, VTT provided Henkel with:

- Deep know-how in cellulose foam and the paper packaging industry

- A pilot line tailored to the customer’s needs

- Help in delivering new formulas, processes and equipment recommendations for customers to use the technology

McLeod said that Henkel achieved all its project objectives, pushing VTT with ambitious performance targets, which sometimes required rethinking process parameters entirely.

“We gave them higher goals,” admitted McLeod. “Sometimes they would say, ‘We’ve never done that before, but we’ll do our best to break through’ – and they did it. Multiple times.”

As a result, Henkel now has a market-ready material and process that can be transferred to customers’ facilities.

“After the intense work at VTT, we have a viable product we can sell and new intellectual property that will generate value for years to come. It’s a step forward not just for us, but for the entire industry,” said McLeod.

Whenever we had a question, they either had someone who could answer it right away or they dug in and did the research to find out.

Bradley McLeod, Business Development Director, Henkel

A partnership built on trust and expertise

Both Pääkkönen and McLeod highlight the close and transparent nature of the collaboration.

“Henkel was very open and worked with us like a single project team. They were quick to test the produced materials and shared the results with the project group,” she said.

McLeod gave thanks to VTT’s talent and professionalism, “It’s impressive to walk into a test setup and see experts running every part of the process. Whenever we had a question, they either had someone who could answer it right away or they dug in and did the research to find out. That kind of depth and responsiveness made a huge difference.”

VTT’s Jouni Lattu, Customer Account Lead, Packaging Value Chain, emphasised how this kind of collaboration builds on VTT’s long-term expertise.

“This project was based on our strong basic research, examining the requirements and opportunities of fibre foam and developing scalable processing solutions. One of VTT’s strengths is the ability to deliver completely tailored piloting projects and processes. We are always prepared to make modifications to our existing pilot lines to answer to each customer’s specific needs,” concluded Lattu.

About Henkel

Henkel is a multinational chemical and consumer goods company headquartered in Düsseldorf, Germany. Founded in 1876, the company is organised into two globally operating business units – Consumer Brands and Adhesive Technologies. Henkel employs around 47,000 people worldwide, with more than 80% working outside of Germany. In 2024, the company reported sales of EUR21.6 billion.