World’s Widest Release Paper Production Line Successfully Started Up

- Specialty paper production with a working width of more than eight metres

- Second complete production line for release paper in China

- Long-standing strategic partnership between Wuzhou Special Paper and Voith

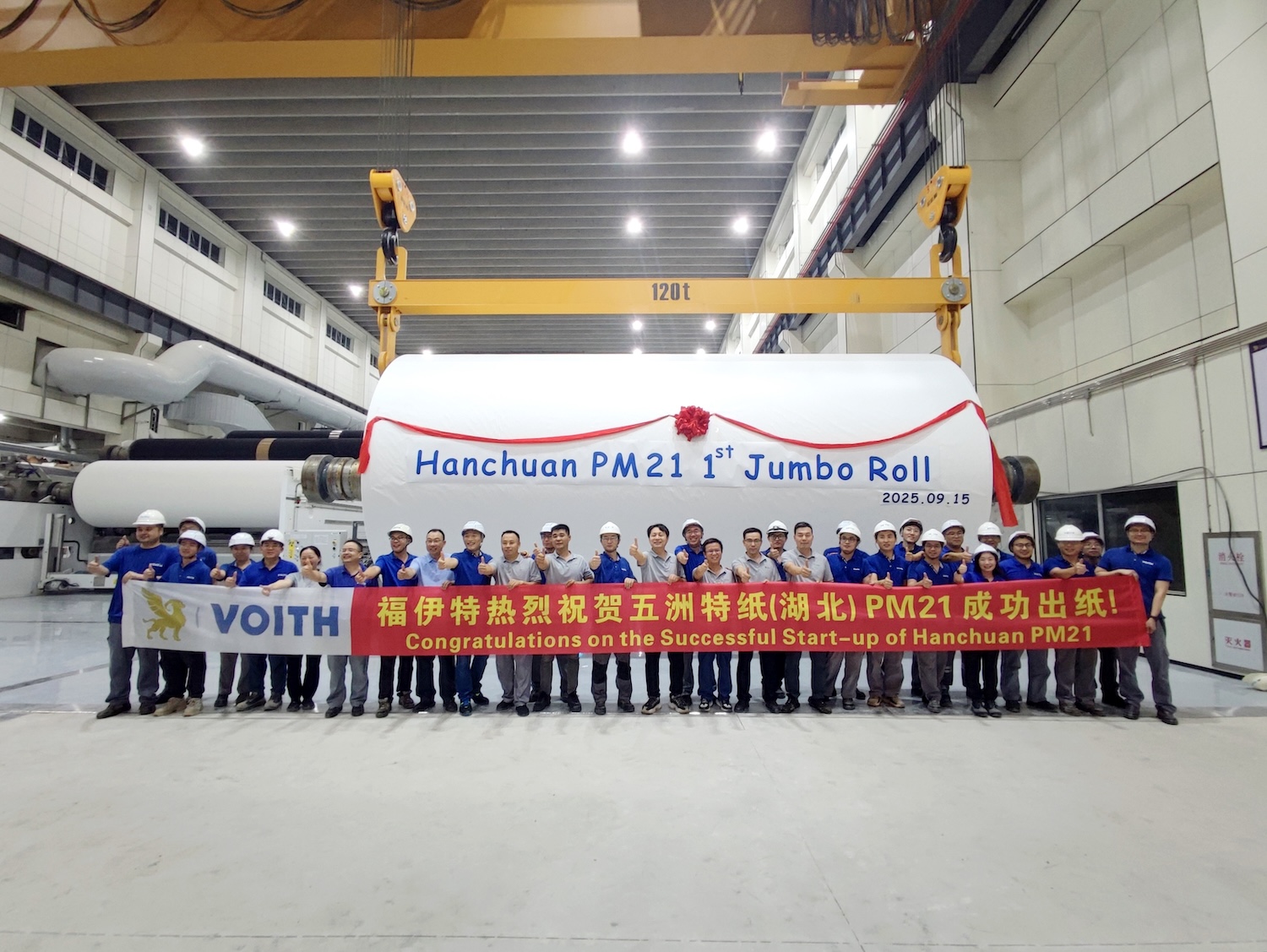

Voith and Wuzhou Special Paper have successfully commissioned the new PM21 specialty paper machine in Hanchuan, Hubei Province. It is the world’s widest machine for the production of release paper. The machine, supplied entirely by Voith, demonstrates the technology group’s leading role in the field of high-quality specialty papers. With a working width of 8.100 metres at the reel, the PM21 produces around 300,000 tons of specialty paper per year with basis weights ranging from 35 to 120g/m² – primarily lightweight release base paper.

Release paper is often used in everyday life to protect sticky surfaces, e.g., in separation applications. The base paper must meet specific requirements in terms of tear resistance, tensile strength, transparency, dense sheet structure and low surface absorbency. It is characterised by a non-stick surface, which is achieved by coating it with silicone.

With the commissioning of PM21, Voith and Wuzhou are continuing their successful strategic partnership. Within this framework, the two companies have already implemented several projects since 2008 and modernised seven paper machines.

The PM21 project is the most important result of our cooperation with Voith. It underscores the company’s global leadership position as a full-line supplier. The plant also lays the foundation for our further growth.

Zhao Lei, Chairman of Wuzhou Special Paper

The PM21 achieves speeds of up to 1,400 metres per minute. A MasterJet Pro F headbox with ModuleJet control and the DuoFormer D II former also make a significant contribution to the performance of the PM21. Voith technologies ensure uniform profiles, optimal moisture distribution and precise fibre orientation. A tandem NipcoFlex shoe press with steam box increases dryness, reduces energy consumption and improves sheet density. This results in an optimal balance between strength and low basis weight.

The SpeedSizer AT film press ensures smooth surfaces and lower silicone consumption, which also improves reverse-side printability. MCB air dryers, combined with ModulePro nozzle humidifiers and a Sirius winding system with automatic tension control, ensure dimensional stability and prevent waviness.

With our experience in quality optimisation, we continue to support Chinese paper manufacturers in their development.

Kurt Yu, President of Voith Paper Asia