Maximising Process Efficiency with Advanced Vacuum Systems in Papermaking

By: Andreas Nakos, Sales & Tendering Manager Paper Industries, Everllence

The paper industry is currently navigating changes, driven primarily by sustained high energy costs and the increasing importance of climate protection. While process efficiency and cost optimisation remain central to maintaining competitiveness, companies are placing growing emphasis on sustainability initiatives and the development of innovative, fibre-based products for diversified markets.

In 2023, global production volumes of board and packaging papers exceeded 265 million tons, with forecasts indicating continued steady growth. However, meeting market demand is no longer sufficient on its own. Increasing regulatory requirements and customer expectations regarding environmental performance are compelling manufacturers to reassess their production processes from an energy and resource efficiency perspective. Particular focus is being placed on energy-intensive stages such as dewatering, where vacuum systems typically account for 20 to 25% of total electrical energy consumption in paper production. Against this backdrop, optimising energy use represents a key lever for both environmental progress and economic efficiency.

Enhancing energy efficiency in paper production

Improving system efficiency presents significant potential for savings. One example of this is the TURBAIR® vacuum system, developed by Everllence in Switzerland. Unlike traditional water ring pumps, which are subject to wear and performance losses over time, these modern vacuum blowers are engineered for stable and efficient operation. Compared to conventional water ring systems, TURBAIR® blowers consume 30% less energy, thanks to a friction-free operating principle that eliminates energy losses caused by water rings. Even higher savings were documented in projects involving the replacement of conventional water ring pumps.

An important feature of the technology is its ability to maintain high efficiency even under partial load conditions. By adapting vacuum levels to the actual demand via frequency-controlled drives, operators can regulate vacuum levels precisely according to production requirements. This load flexibility enables additional energy savings of up to 35% and prevents avoidable energy loss due to system over-expansion. In certain applications, further reduction of up to 20% can be achieved by fine-tuning process parameters.

Moreover, TURBAIR® systems eliminate the need for sealing water, reducing not only operating costs but also water consumption and environmental impact. Another key advantage is the potential for waste heat recovery: the hot exhaust air produced during operation – typically reaching temperatures between 120°C and 165°C -can be captured using heat exchangers. Up to 80% of the input drive energy can be recovered and repurposed within the plant, for example for process water heating or building heating.

With the combined effect of these measures, the total energy consumption of vacuum systems in paper production can be reduced by up to 80% by replacing water ring pumps with Everllence’s highly efficient TURBAIR® blower system. As energy efficiency and sustainability become decisive factors for industrial competitiveness, modern vacuum technology represents a critical lever for paper manufacturers seeking to lower both their environmental footprint and operating costs.

Flexible vacuum blower solutions for diverse paper applications

Modern papermaking processes require vacuum systems that can adapt to a wide range of operational demands. To address this, manufacturers can choose between single-stage and multi-stage vacuum blower solutions, each optimised for specific process areas and performance requirements.

The single-stage RT blower offers capacities ranging from 200 to 1,450m3/min and vacuum levels of up to 65 kPa. Equipped with automatic outlet regulation, it allows for dynamic adjustment of the airflow in response to changing production needs. This makes the RT series particularly effective for applications such as felt conditioning in tissue production, where operating conditions can fluctuate significantly.

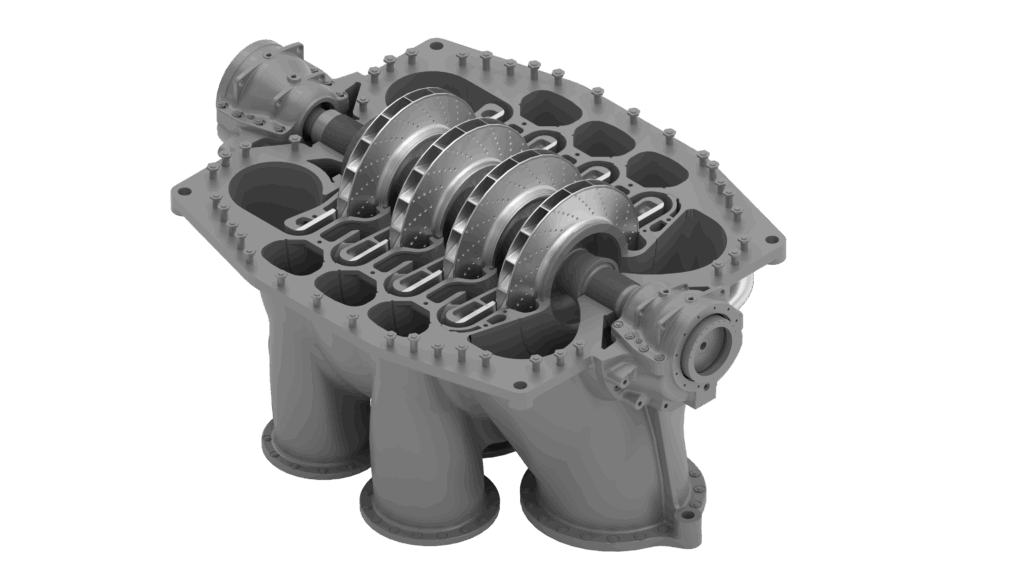

For higher-capacity and multi-level vacuum applications, the multi-stage RC blower provides a robust solution. With up to four suction nozzles and four separate vacuum levels, the RC blower offers a capacity range between 180 and 3,000m3/min and vacuum levels reaching up to 75 kPa. Designed for high-demand production environments, the RC blower is particularly well suited for graphic paper, board, and pulp manufacturing, where stable vacuum performance is critical to process stability.

TURBAIR® multi-stage RC blower by Everllence